Technology

Customized antenna products provide optimized performance to support device/product wireless connection. Normally we process customized antenna procedures as follows.

Review – Review customer’s specification & requirement

Review and define the most suitable antenna specification (2.4GHz Wifi Antenna)

Discuss Cost/ Performance trade-off

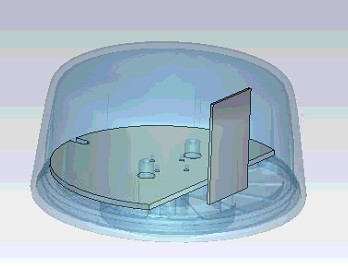

Suggest PCB/ Metal layout

Lynwave needs to receive the customer’s 3D drawing in STP file and PCB layout to go to the next step.

Design – Provide antenna selections & placement

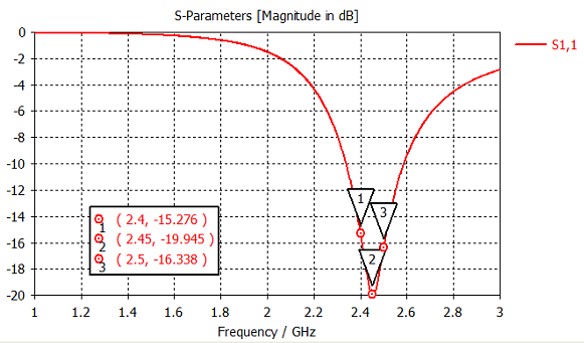

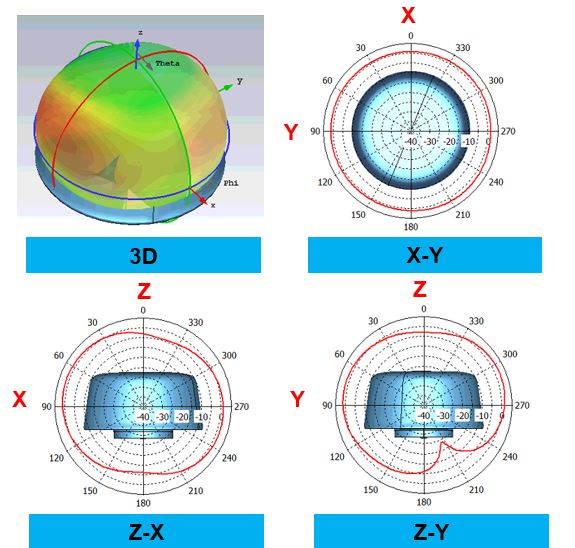

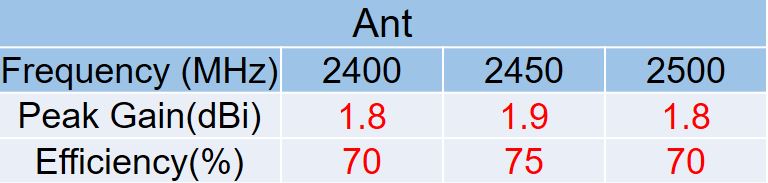

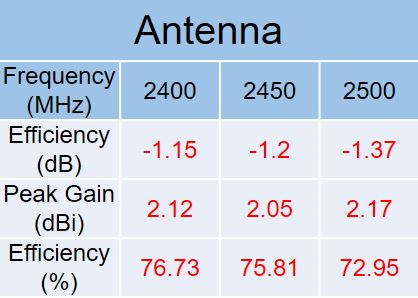

Provide Wifi antenna simulation reports (S11 return loss, S21 isolation value, Gain value, Efficiency & radiation pattern)

Fix layout location

Maximize performance

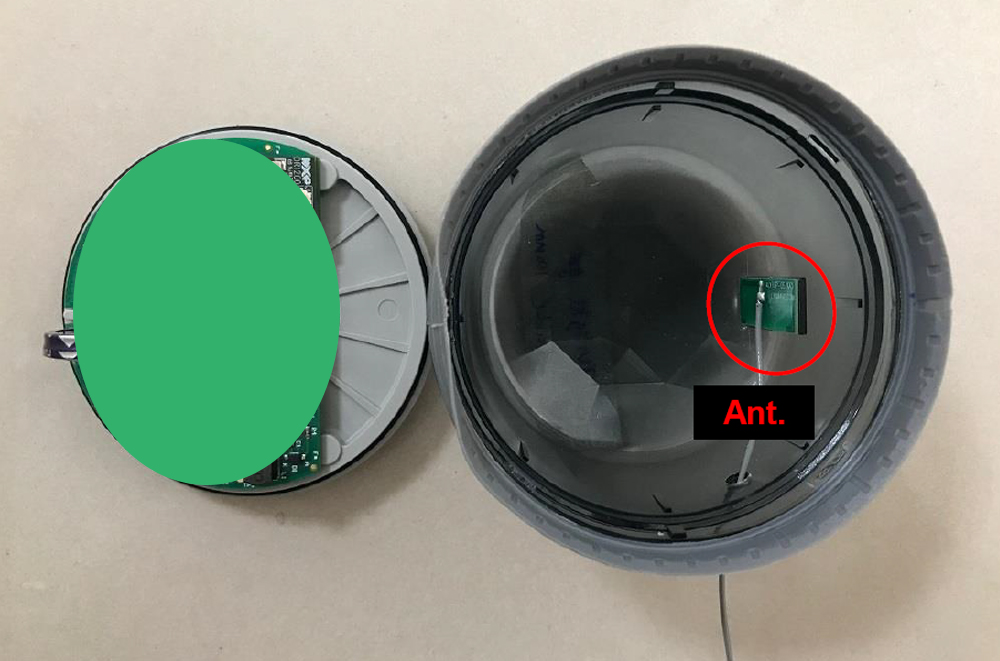

Lynwave needs to receive the customer’s PCBA and mock-up housing for the next step.

V & V – Verification an Validation

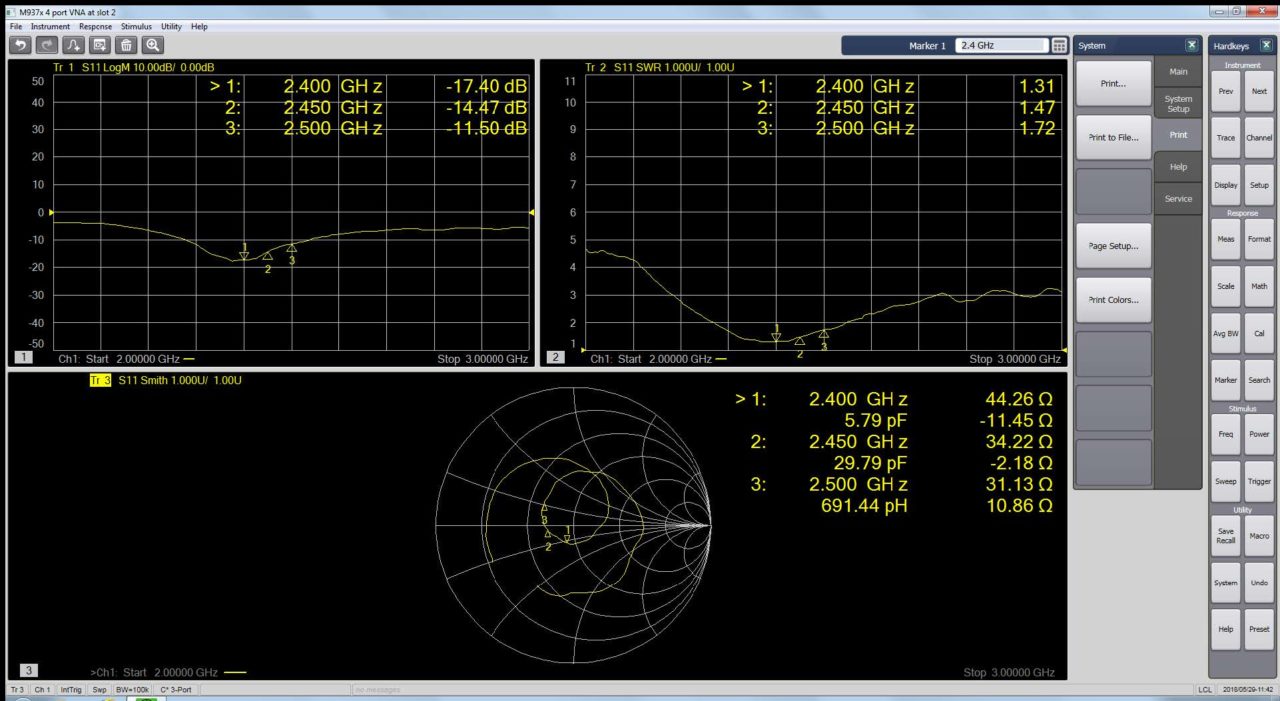

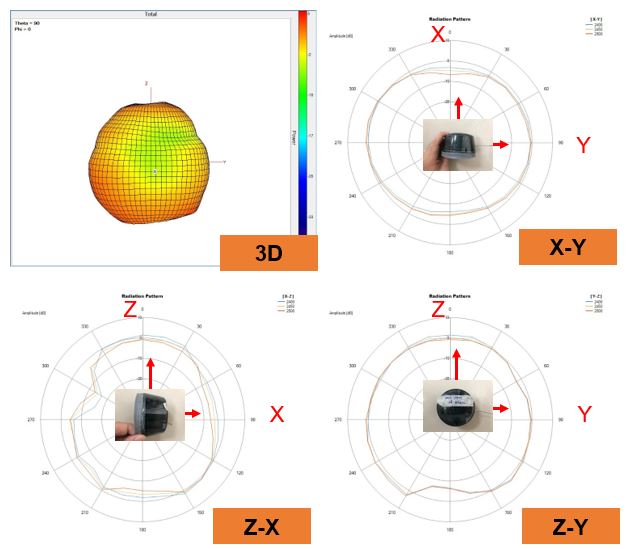

Verification: Performance Test & Integration Test

Validation: Prototyping Sample, Throughput test report & design for manufacturing

Manufacture – Mass Production & Quality Control

BOM confirmation

Tooling preparation (if needed)

Material preparation

Mass Production SOP set-up

Production Pilot Run

Mass Production

Test & Quality Report