Antenna Design + Thermal Design= ?

Wi-Fi initially was a single stream, with a single client talking to a router (1×1). It has evolved into an 8×8 MIMO (multiple input/multiple output) solution where multiple clients talk to a router at the same time. The current Wi-Fi standard, 802.11ac (Wi‑Fi 5), was fully released in late 2013, and it works very well in a home environment. As with previous Wi-Fi standards, it may reach its limits around 2022 when there could be 50 nodes in a home.

802.11ax (now called Wi‑Fi 6) is the next evolution in the IEEE 802.11 Wi-Fi standard and will become prevalent in very dense environments. Urban apartment complexes, college campuses, concert venues, or sports stadiums, where many clients will access the internet over Wi‑Fi. The IEEE standard currently is in development and expected to be publicly released in 2019.

Due to Wi‑Fi 6 (802.11ax) pushes the EVM requirements down to -47 dB, but access points and clients still have to meet the same spec. Power levels can be very different, though, access points or customer premises equipment (CPE) typically operate at much higher power than a client — 24 dBm versus 14-20 dBm for a mobile handset. Ultimately, a lot more power means a lot more heat that has to be dissipated, so a connectivity solution may require a more stringent thermal requirement compared to a mobile solution.

Currently, our customer meet a lot of thermal issue on their device. Their designed device would become ‘VERY HOT’ while in working stage. Full of heat sink need to be added to reduce the working temperature and pass the thermal certified specification. This may impact the cost and the placement of antenna. LYNwave provide ” Antenna & Thermal Integrated Solution” to help our customer to overcome this HOT and wireless performance issue.

Here are the advantage to take our integrated design as solution:

- Integrated antenna and thermal solution

- Increase antenna performance

- shorten development process & schedule

- Improve production reliability

- Compact Space

- Cost reduction

Actual Device Case Study

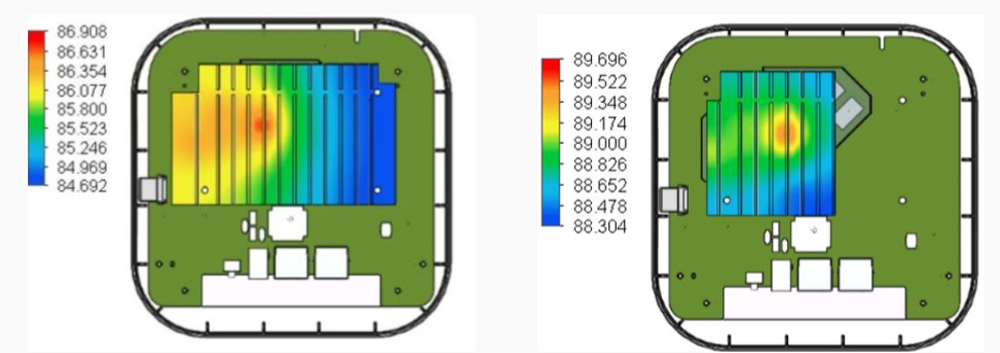

Above picture shows that our team success to combine our thermal & antenna design to help our customer have 40% heat sink material saving and keep the temperature only increase 2%.

Optimized : Antenna Design + Thermal Design

Saving: Heat Sink Material + Time of communication

You could visit to our “Thermal Solution Design Service” page for more information.