Our Services

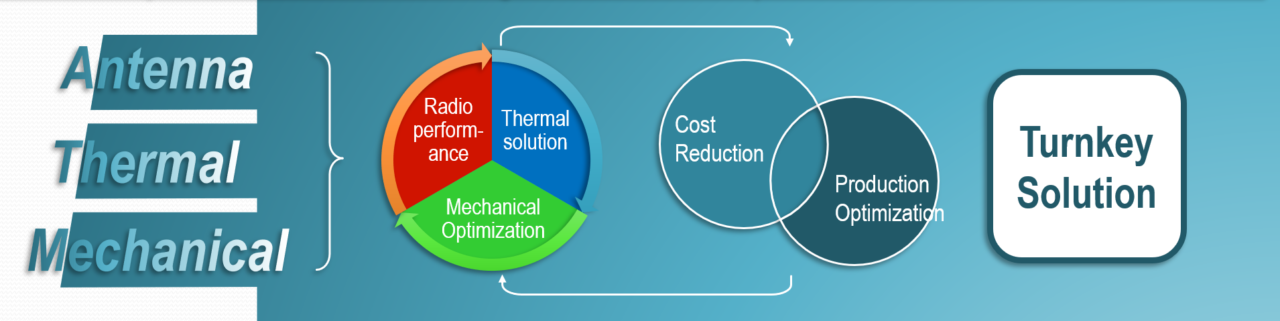

LYNwave has been developing optimized solutions of customized antenna, thermal, mechanical and outdoor enclosure designs based on reliable simulation technologies, providing comprehensive high-performance antennas and services such as 3D printing, throughput testing and Wi-Fi test house testing to realize your IoT programs.

Thermal Solution Designs

We produce RF antennas with experienced experts

We provide thermal solutions for units that need heat dispatching

We integrate the parts with optimized mechanical reviews

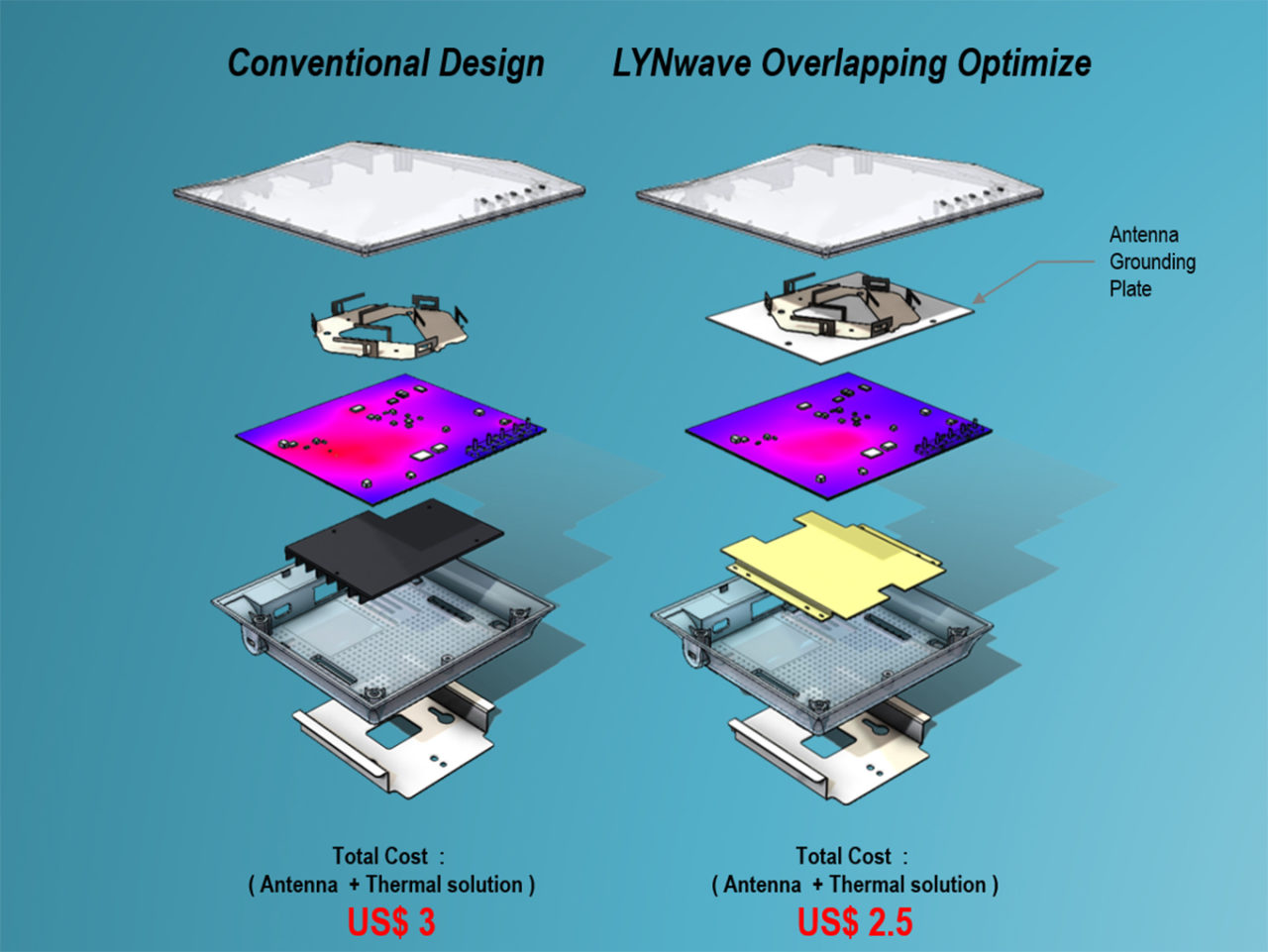

In the conventional project process, we always see the design has been applied separately, which means the costs are counted separately and summed together. Although, many materials can be shared to use, as the heat can be dispatched through proper antenna materials, the antenna can be shared to use the heat plate as a grounding plate, and an EMC shielding cover can be replaced by a heat solution.

We do the overall design to reduce the cost and optimize the space. Moreover, we provide the solution for you to reduce the labor cost on the assembly line.

Skill overlapping training:

Our trained individual experts have basic understandings of requirements and limitations for other technology to reduce the design conflict, further reducing the overall design iteration. On the other hand, our individual experts can understand the material characteristics which can be shared to apply to the function requirement. Sharing material (parts) is our target to reduce the space and cost for the total solution.

Group design discussion:

Individual experts work as a task force for each project as we implement collaborative work with real-time design and brain-storm communication to reduce the design stage period.

Overlapping Optimization

With the “LYNwave Overlapping Optimization“ design, we share the materials between the antenna and thermal conductive materials, so do mechanical parts.

By adding the antenna grounding plate, the following of the RF performances can be increased:

– Higher RF Coverage

– Better EMI Isolation

– Higher Antenna Efficiency

We figure to utilize the plate to thermal conductive to dispatch the heat, and arrange to conduct the heat outside the enclosure as well by replacing the bottom heat sink with a cost-effective metal plate.

We utilize the material cross-functionally, to increase the overall performance without adding cost, but decrease the cost.

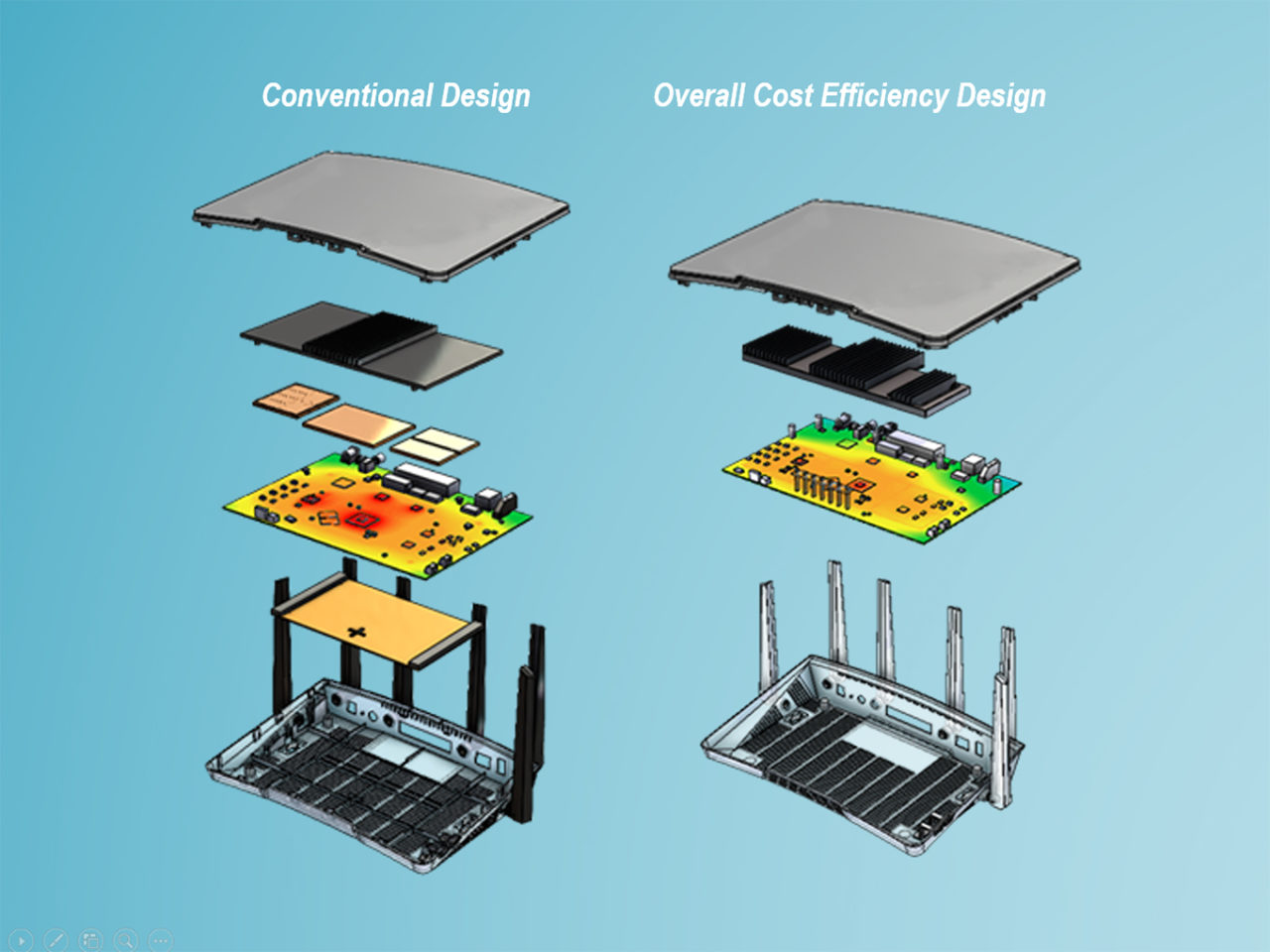

Cost Efficiency Design

Thermal designing with overall material consideration to reduce total cost.

Conventional Design LYNwave Overall Design

1. Top heat sink 1. Single high performance

2. Bottom heat sink heatsink with EMI shielding

3. EMI shielding cover cover function

4. Multiple thermal pads

5. Complicated assembly labor cost

Total Cost: US$ 8.5 Total Cost: US$ 6

With experienced technicians associated with group design workflow of years, we provide the solution not only to resolve individual function requirements, but also to reduce the material preparation time from IQC, IPQC, Production floor, OQC, considering with production cost, to provide a simple and robust unit design under budget.

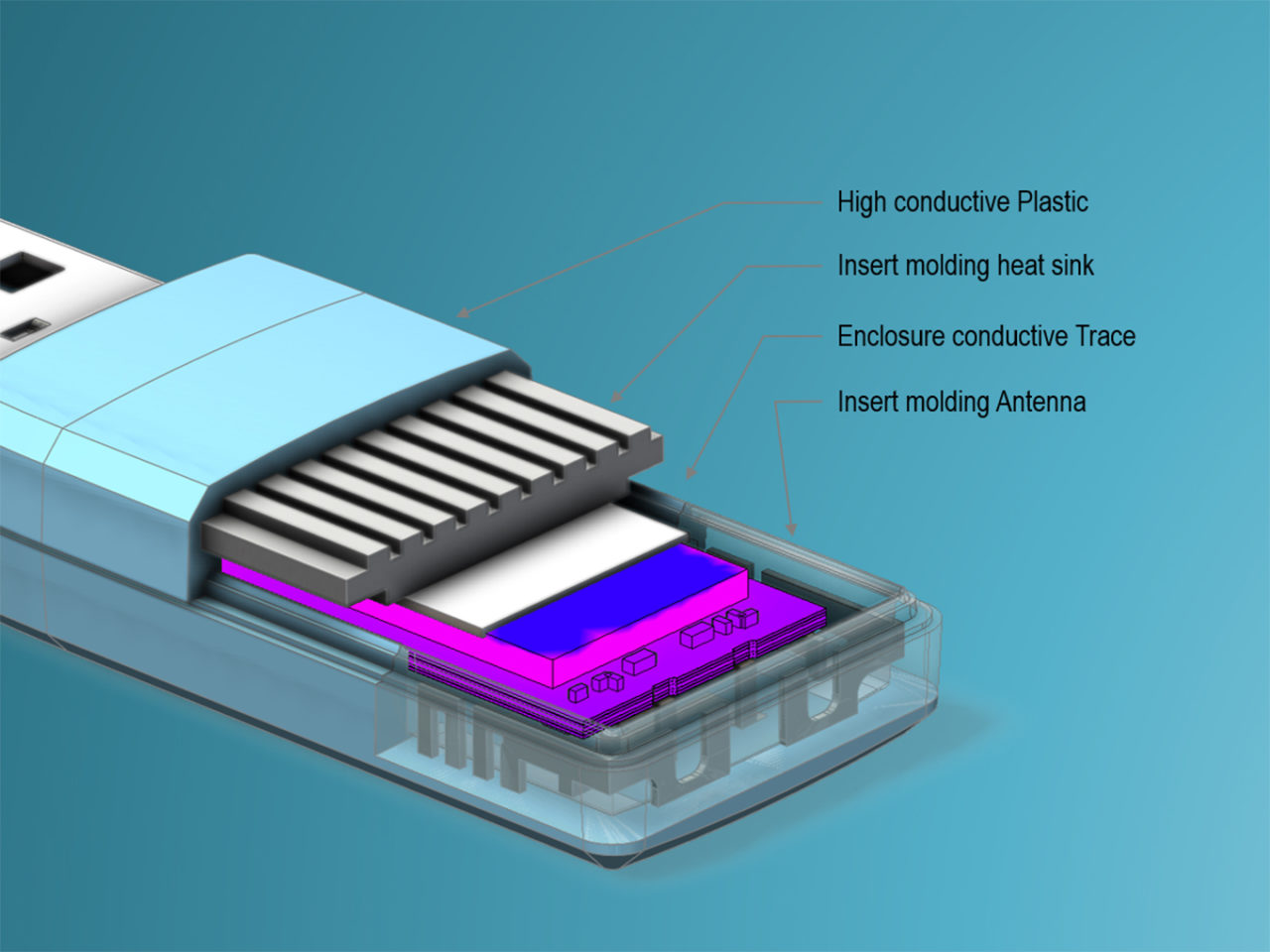

Group Overlap Design

LYNwave thermal group has sound knowledge

of the industrial material characteristics to design

the thermal solution and implement the RF performance at the same time. So we can re-solve the functional conflict project within a limited

dimension on different applications.

High heat dispatching requires highly conductive materials such as metals, which will block and impact the RF characteristics well. However, with LYNwave grouping design discussion, we implement suitable materials with the

manufacturing identical process to achieve cross-function requirements.

If you have more questions about our Thermal Solution, feel free to contact us to have quick discussion with us on your needs first. LYNwave is looking forward to supporting you throughout the process.